Новое поступление

M14 * 1 неработающий шпиндель токарного станка 50/63/65 патрона | Инструменты

Высокая точность литья металла шпинделя двигателя 3.5Kw AC380V с водяным охлаждением

Комплекты шпинделей с ЧПУ 500 Вт электродвигатель шпинделя воздушным охлаждением

Any Size Custom planer spindle shaft helical cutterhead for Makita 2012NB thickness spiral cutter head | Инструменты

Мотор с воздушным охлаждением 800 кВт Вт для гравировального станка ЧПУ |

Квадратный фрезерный станок с ЧПУ 600 Вт постоянный ток бесщеточный

15 25 типов пневматическое зажимное сиденье приспособление для транспортных

HYCNCPARTS Store

Магазина HYCNCPARTS Store работает с 01.01.2017. его рейтинг составлет 91.97 баллов из 100. В избранное добавили 2256 покупателя. Средний рейтинг торваров продавца 4.7 в продаже представленно 913 наименований товаров, успешно доставлено 1416 заказов. 386 покупателей оставили отзывы о продавце.

Характеристики

3.2kw spindle water cooled kit er20 milling motor +4KW VFD+ 100 clamp + pump +10m cable for CNC Router | Инструменты

История изменения цены

*Текущая стоимость 36 265,94 - 37 693,73 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-15-2025 | 46057.81 руб. | 46978.71 руб. | 46517.5 руб. |

| Jul-15-2025 | 37353.68 руб. | 38100.91 руб. | 37726.5 руб. |

| Jun-15-2025 | 45331.57 руб. | 46238.9 руб. | 45784.5 руб. |

| May-15-2025 | 44969.22 руб. | 45868.80 руб. | 45418.5 руб. |

| Apr-15-2025 | 35902.38 руб. | 36620.0 руб. | 36261 руб. |

| Mar-15-2025 | 44243.32 руб. | 45128.37 руб. | 44685.5 руб. |

| Feb-15-2025 | 43881.30 руб. | 44759.59 руб. | 44320 руб. |

| Jan-15-2025 | 43518.43 руб. | 44388.90 руб. | 43953 руб. |

Описание товара

- 3.2kw ER20 water-cooled stone spindle

- Rituo 4kw inverter

- 3.5m water pump

- 10 meters 3*1 line

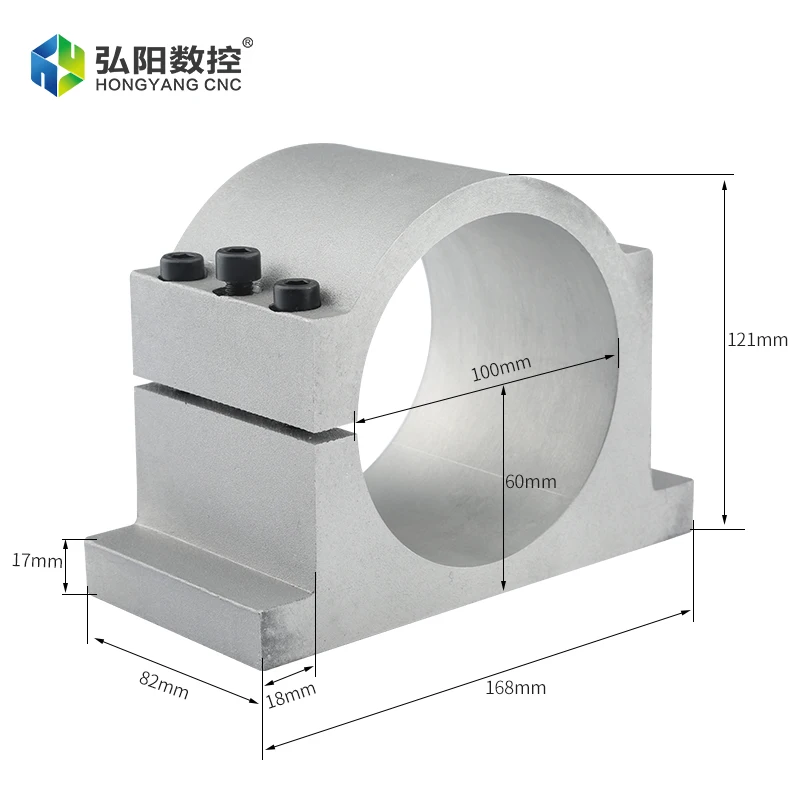

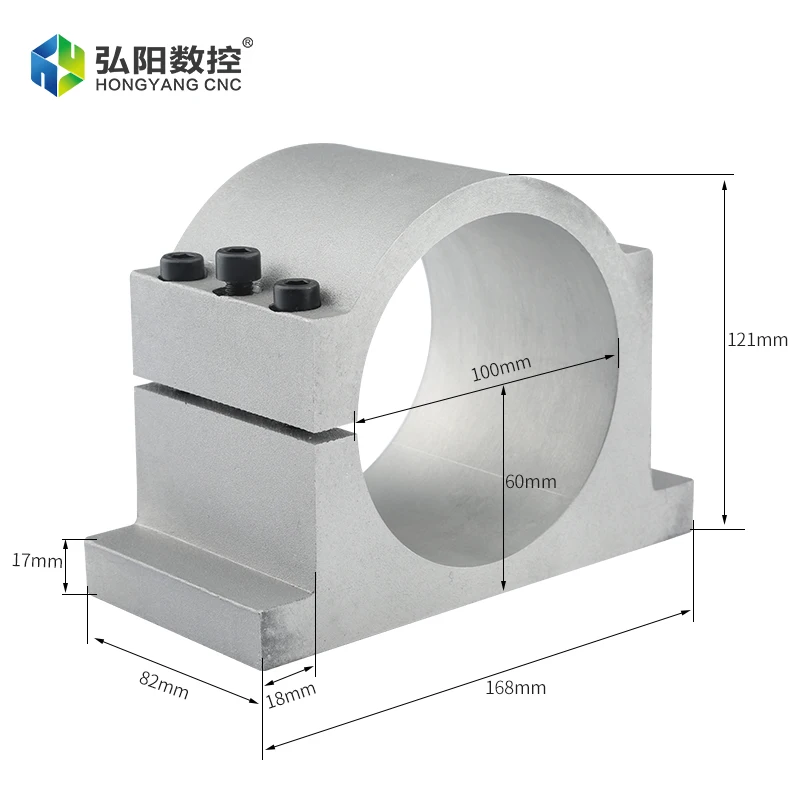

- 100 round fixture

Dimensions: φ100x290mm

Speed possibility: Change the spindle speed by three-phase output inverter and setting the inverter frequency.

Cooling method: water cooling

Power interface: optional H20 -4 pin waterproo F air connector.

The air connectors labeled "1", "2", "3", "4", "1", "2", "3" are connected to the frequency converter (U, V, W), 4 are connected to the frequency converter On the bottom plate.

Dimensions: φ100x290mm

Speed possibility: Change the spindle speed by three-phase output inverter and setting the inverter frequency.

Cooling method: water cooling

Power interface: optional H20 -4 pin waterproo F air connector.

The air connectors labeled "1", "2", "3", "4", "1", "2", "3" are connected to the frequency converter (U, V, W), 4 are connected to the frequency converter On the bottom plate.

Power: 3.2 kW

Voltage: 220v

Current: 10A

Frequency: 400Hz

Speed: 0-24000rpm

Runout: less than 0.01mm

Diameter (mm): 100

Bearing type: 2x7005 P4 DT & 2x7003 P4 DT

4 fully sealed ceramic ball bearings

Chuck: ER20

Cutter diameter: 13mm, 12mm, 12.7mm, 11mm, 10mm, 9mm, 8mm, 7mm, 6.35mm, 6mm, 5mm, 4mm, 3.175mm, 3.0mm, 2.5mm, 2mm, 1.2mm, 1mm (standard 6mm)

Water-cooled ER20 chuck block

Grease lubrication

Main use: used for wood, stone, bamboo, ordinary PCB, PVC, PMMA, plastic, bamboo, two-tone board (ABS) and other non-metallic carving, also can be on gold, silver, copper, aluminum, Pb and other soft metal surfaces Carved on.

Power: 3.2 kW

Voltage: 220v

Current: 10A

Frequency: 400Hz

Speed: 0-24000rpm

Runout: less than 0.01mm

Diameter (mm): 100

Bearing type: 2x7005 P4 DT & 2x7003 P4 DT

4 fully sealed ceramic ball bearings

Chuck: ER20

Cutter diameter: 13mm, 12mm, 12.7mm, 11mm, 10mm, 9mm, 8mm, 7mm, 6.35mm, 6mm, 5mm, 4mm, 3.175mm, 3.0mm, 2.5mm, 2mm, 1.2mm, 1mm (standard 6mm)

Water-cooled ER20 chuck block

Grease lubrication

Main use: used for wood, stone, bamboo, ordinary PCB, PVC, PMMA, plastic, bamboo, two-tone board (ABS) and other non-metallic carving, also can be on gold, silver, copper, aluminum, Pb and other soft metal surfaces Carved on.

The front end of the P4 fully sealed angular contact ball bearing 7003 and the rear end of 7005 can extend the life of the spindle.

1. Our ceramic ball bearing spindle uses 4 pieces of ceramic ball bearings.

2. Ceramic ball bearings are resistant to high temperature and low heat. When used, they are usually 3-5 degrees lower than steel ball bearings.

3. Ceramic ball bearings have low friction, low noise and long life.

4. If the main shaft is to be used for aluminum and hardwood, ceramic ball bearings are better than steel ball bearings.

1. Our ceramic ball bearing spindle uses 4 pieces of ceramic ball bearings.

2. Ceramic ball bearings are resistant to high temperature and low heat. When used, they are usually 3-5 degrees lower than steel ball bearings.

3. Ceramic ball bearings have low friction, low noise and long life.

4. If the main shaft is to be used for aluminum and hardwood, ceramic ball bearings are better than steel ball bearings.

Product power: 4.0kw Model: HL3000-4040-T

Input voltage: 2PH380V Input frequency: 50/60Hz

Output voltage: 3PH0-380V Product current: 9.5A

Product power: 4.0kw Model: HL3000-4040-T

Input voltage: 2PH380V Input frequency: 50/60Hz

Output voltage: 3PH0-380V Product current: 9.5A

◆Two speed control modes: no PG vector control (SVC), V/F control

◆ Vector control without PG (SVC): starting torque 0.5 Hz, maximum 150%

◆ 8-segment simple PLC function, multi-segment speed control and pid control

◆Support multiple frequency settings: digital settings, analog settings, PID settings, RS485 communication settings

◆ I/O terminals can be freely programmed to combine multiple working modes according to user needs.

◆With frequency hopping control function, it can effectively suppress mechanical resonance and make the system more stable and reliable.

◆It has the function of instantaneous power-off retention, which can avoid the impact on production due to instantaneous power-off

◆With over-torque and under-torque detection

◆Automatic voltage setting function, effectively solve the problem of low frequency vibration of high-power motors

◆Provide multiple fault protection functions: overcurrent, overvoltage, undervoltage, overheat, overload, lack of real-time monitoring and protection to ensure safe operation

◆Two speed control modes: no PG vector control (SVC), V/F control

◆ Vector control without PG (SVC): starting torque 0.5 Hz, maximum 150%

◆ 8-segment simple PLC function, multi-segment speed control and pid control

◆Support multiple frequency settings: digital settings, analog settings, PID settings, RS485 communication settings

◆ I/O terminals can be freely programmed to combine multiple working modes according to user needs.

◆With frequency hopping control function, it can effectively suppress mechanical resonance and make the system more stable and reliable.

◆It has the function of instantaneous power-off retention, which can avoid the impact on production due to instantaneous power-off

◆With over-torque and under-torque detection

◆Automatic voltage setting function, effectively solve the problem of low frequency vibration of high-power motors

◆Provide multiple fault protection functions: overcurrent, overvoltage, undervoltage, overheat, overload, lack of real-time monitoring and protection to ensure safe operation

Maximum head: 3.5m Power: 80w

Maximum flow: 3500L/H Plug cable length: 1.5m

Voltage: 220V Frequency: 50Hz

Outer diameter of the nozzle: 6mm size: 110x120x170mm

High lift

Large Flow

Very durable

Excellent insulation

Can cool the machine quickly

Good quality and long life

Large inventory

Powerful performance

The housing is made of high-quality plastic, which is resistant to corrosion and highly durable.

Because the motor bearings are completely sealed, the pump has excellent insulation properties.

Must be used in water.

Once the product is not working properly, the power must be cut off and must be kept after lifting it from the water.

Maximum head: 3.5m Power: 80w

Maximum flow: 3500L/H Plug cable length: 1.5m

Voltage: 220V Frequency: 50Hz

Outer diameter of the nozzle: 6mm size: 110x120x170mm

High lift

Large Flow

Very durable

Excellent insulation

Can cool the machine quickly

Good quality and long life

Large inventory

Powerful performance

The housing is made of high-quality plastic, which is resistant to corrosion and highly durable.

Because the motor bearings are completely sealed, the pump has excellent insulation properties.

Must be used in water.

Once the product is not working properly, the power must be cut off and must be kept after lifting it from the water.

Diameter: 80 mm

Material: Cast aluminum

Compared with aluminum profiles, its accuracy is much higher, and it is difficult to deform.

The inner wall is very smooth, and the outer wall is sandblasted, relatively thin, not even smooth.

Cast aluminum lamps are much heavier than aluminum profiles.

Cast aluminum lamps and lanterns are high-quality aluminum cast by a special manufacturing process. Compared with ordinary aluminum, this product has toughness, strong impact resistance, high hardness and strong antioxidant activity.

Mainly used for product fixing, so the balance and verticality of by-products improve the accuracy of auxiliary products, reduce noise, and reduce cumulative errors.

Diameter: 80 mm

Material: Cast aluminum

Compared with aluminum profiles, its accuracy is much higher, and it is difficult to deform.

The inner wall is very smooth, and the outer wall is sandblasted, relatively thin, not even smooth.

Cast aluminum lamps are much heavier than aluminum profiles.

Cast aluminum lamps and lanterns are high-quality aluminum cast by a special manufacturing process. Compared with ordinary aluminum, this product has toughness, strong impact resistance, high hardness and strong antioxidant activity.

Mainly used for product fixing, so the balance and verticality of by-products improve the accuracy of auxiliary products, reduce noise, and reduce cumulative errors.

This product uses a thickened outer sheath made of new materials, which is green and environmentally friendly, waterproof, oil-proof, folding-resistant, wear-resistant, and has a long service life.

The shielding net can effectively prevent partial discharge between the conductor and the insulator layer, and has strong anti-interference ability.

①The working temperature of the spindle is usually -10~40. ②Before installing the first electro-spindle and turning it by hand, you should feel flexible and non-blocking.

Use correctly

①During the maintenance and transportation of the spindle, the bearing conditions inside the high-speed grease will change, and the customer should run at a low speed for 30 minutes. Then slowly increase the speed at 3000 rpm for 20 minutes each time. The spindle and inverter should work together. The specifications and parameter settings of the inverter match the spindle parameters. ②Connect the main shaft of the inverter, and solder the three-phase inverter power cable to the 1 (U), 2 (V), 3 (W) pins of the plug, and the 4 pins of the floor. After turning on the power, observe whether the spindle rotation axis always shows the direction. If any discrepancy is found, it should be shut down immediately, please replace the inverter and the spindle connected by the two wires of the three-phase power supply. ③Make sure that the cooling system is correct before using the water-cooled spindle. Before using the spindle every day, it must run at low speed for 15-20 minutes. Clamp the cutter to the spindle, collet nut, collet, and cutter must be clean enough. The shank inserted into the chuck must be larger than 15mm.

①Water-cooled spindles must be used with water pumps. Otherwise, the spindle will break quickly. ②The AC spindle motor must be used with the inverter. The inverter power needs to be equal to or greater than the spindle power. Before setting, please set the inverter parameters suitable for the spindle. Otherwise, the spindle and inverter will break immediately. ③If the spindle is used, the noise will be different from the past, so stop the spindle immediately. You need to replace the spindle bearing.

Company information and contact information

Jinan Hongyang CNC Machinery Co., Ltd. was established in 2015. There are more than 100 employees, and the inventory area is 10,000 square meters. It is mainly engaged in engraving machine parts, including spindle motor, frequency converter, stepper motor, drive, hybrid servo motor, servo motor, Richauto dsp series controller, weihong or nc studio controller, spindle cooling water pump, lubricating oil pump, tool sensor, Limit sensors, water-cooled vacuum pumps, air-cooled vacuum pumps, power supplies, transformers, gear boxes, racks, rails, sliders or blocks, ISO30 tool clips, cable chains, spindle dust covers, vacuum cleaners and other engraving machine accessories, welcome your For inquiries.

Contact information

WeChat whatsapp mobile 8615650000988

lily @ hycncrouter. com

Company information and contact information

Jinan Hongyang CNC Machinery Co., Ltd. was established in 2015. There are more than 100 employees, and the inventory area is 10,000 square meters. It is mainly engaged in engraving machine parts, including spindle motor, frequency converter, stepper motor, drive, hybrid servo motor, servo motor, Richauto dsp series controller, weihong or nc studio controller, spindle cooling water pump, lubricating oil pump, tool sensor, Limit sensors, water-cooled vacuum pumps, air-cooled vacuum pumps, power supplies, transformers, gear boxes, racks, rails, sliders or blocks, ISO30 tool clips, cable chains, spindle dust covers, vacuum cleaners and other engraving machine accessories, welcome your For inquiries.

Contact information

WeChat whatsapp mobile 8615650000988

lily @ hycncrouter. com

Смотрите так же другие товары: