Новое поступление

Низкая стоимость 6090 мини ЧПУ 6060 маршрутизатор/4 оси cnc древесины гравировальный

Цзинань 6090 многоголовый шпиндель 3D фрезерный станок с ЧПУ 3.0kw 1212 цена |

AI PLT DXF BMP DST DWG LAS DXP ручной тип CE cnc волоконная лазерная маркировочная машина для

Плазменный резак Сделано в Китае высокоскоростной станок для резки металла цена

Лазер Jinan режущий станок 600x900x150 мм cnc 6090 Лазерная резка гравировальный |

Станок для лазерной резки металла и нержавеющей стали Reci 1300 Вт 900 стальной ЧПУ

China discount price 1610 1390 wood acrylic laser cutting machine co2 3d engraving | Инструменты

Характеристики

Универсальный 2030 cnc 3d деревообрабатывающий станок | Инструменты

История изменения цены

*Текущая стоимость 455 410,72 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-18-2025 | 541938.46 руб. | 569035.53 руб. | 555486.5 руб. |

| Aug-18-2025 | 537384.0 руб. | 564253.26 руб. | 550818.5 руб. |

| Jul-18-2025 | 450856.99 руб. | 473399.53 руб. | 462127.5 руб. |

| Jun-18-2025 | 528276.46 руб. | 554690.4 руб. | 541483 руб. |

| May-18-2025 | 459964.70 руб. | 482962.65 руб. | 471463 руб. |

| Apr-18-2025 | 519167.43 руб. | 545125.51 руб. | 532146 руб. |

| Mar-18-2025 | 514613.34 руб. | 540344.50 руб. | 527478.5 руб. |

| Feb-18-2025 | 510059.24 руб. | 535562.63 руб. | 522810.5 руб. |

| Jan-18-2025 | 505505.59 руб. | 530780.85 руб. | 518142.5 руб. |

Описание товара

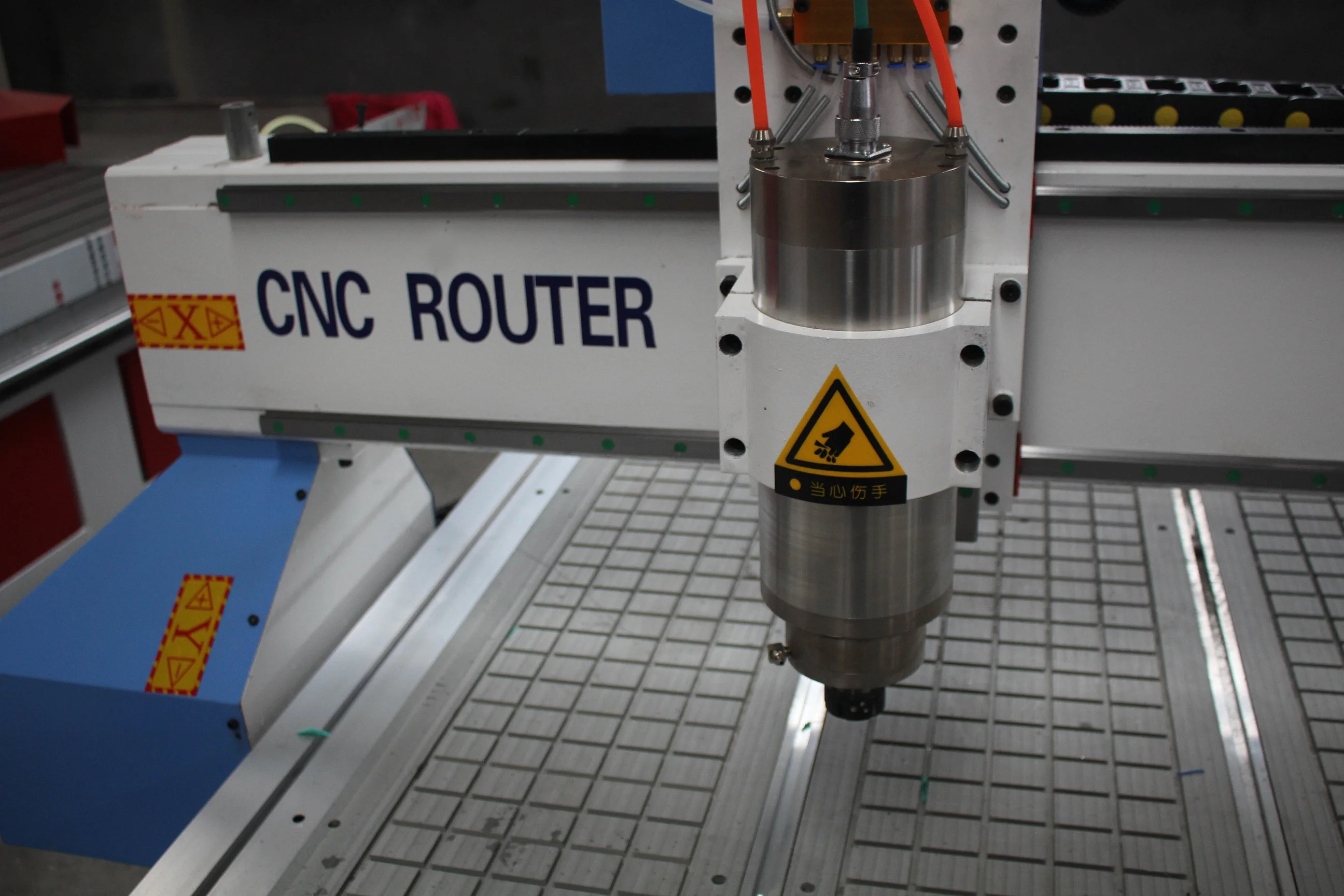

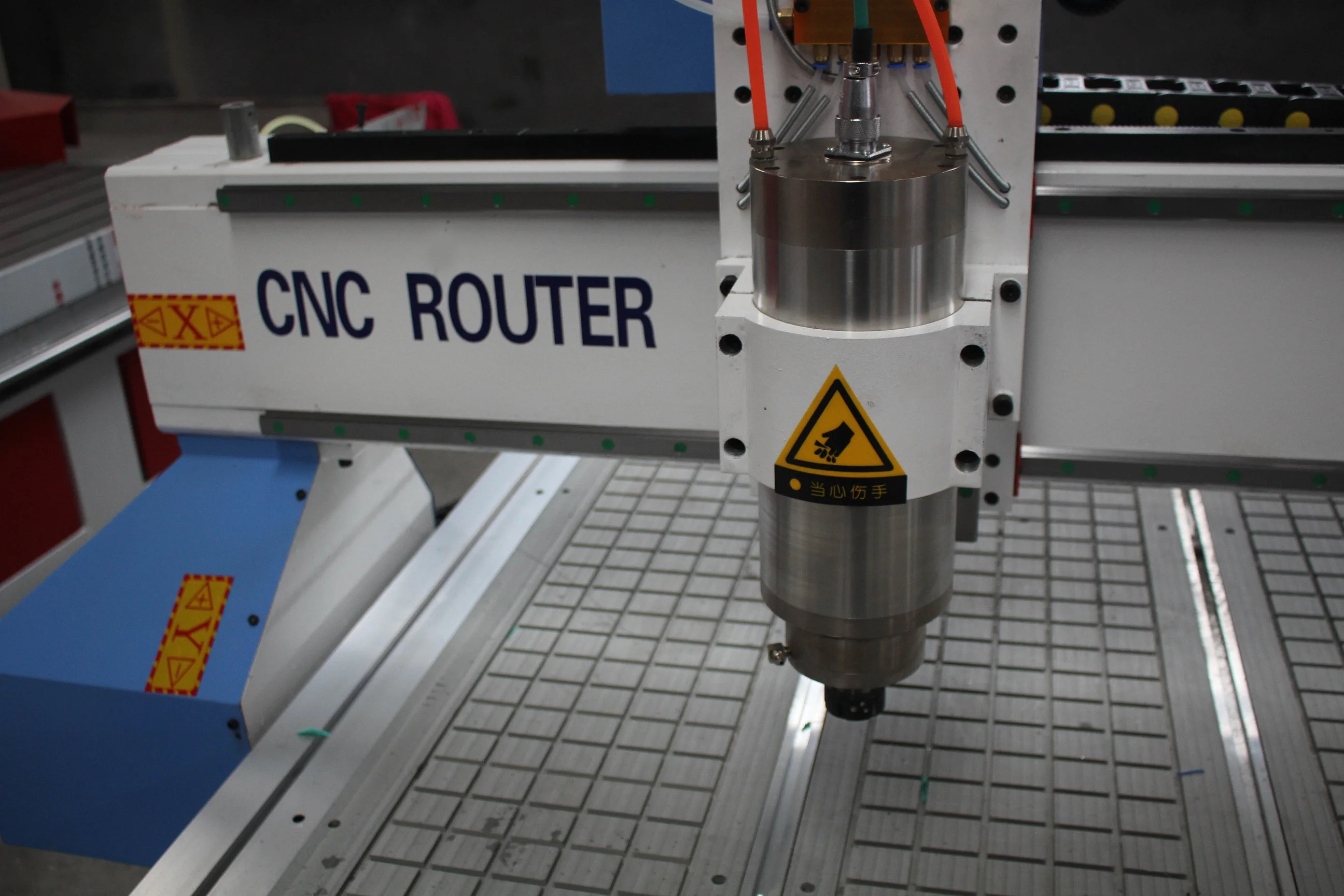

Universal 2030 cnc 3d wood router machine

Product Description

characteristic

1.Water cooling spindle,high precision,long life time,steady working,easy to start up.

2.thicken square pipe stucture ,well welded, no distortion for whole structure high precision ,and long life time.

3.DSP controller system with USB interface,working without connecting with computer during working and easy to control.

4.Software:CAD/CAM designing software such as type3/artcam/castmate/weitai etc.

5.auto oilling system ,easy to operate by pressing one key.

6.seperated control system makes operation easily.

7.Adopt high speed stepper motor and drivers,and two motors for Y axis.max speed is 25mm/min.

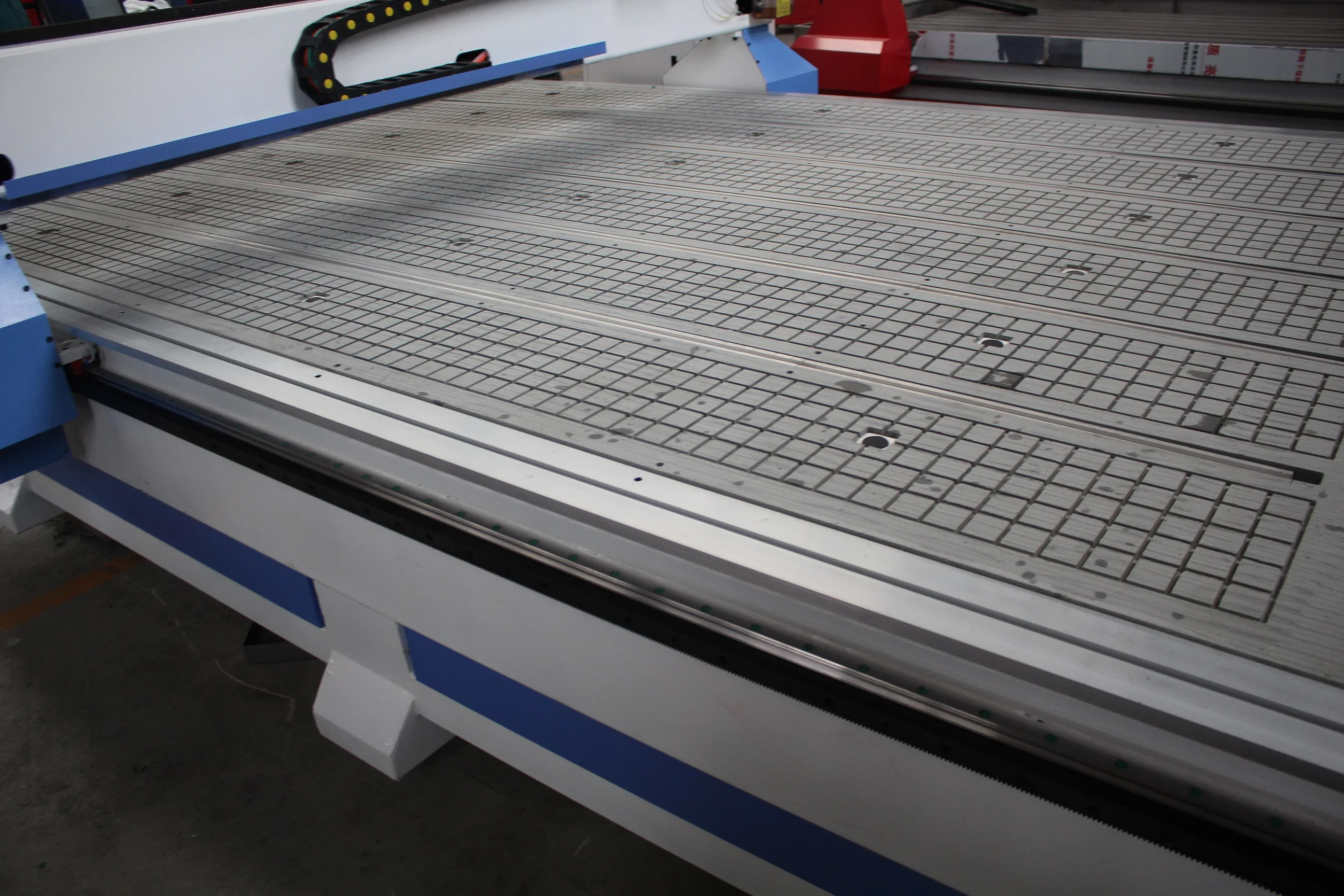

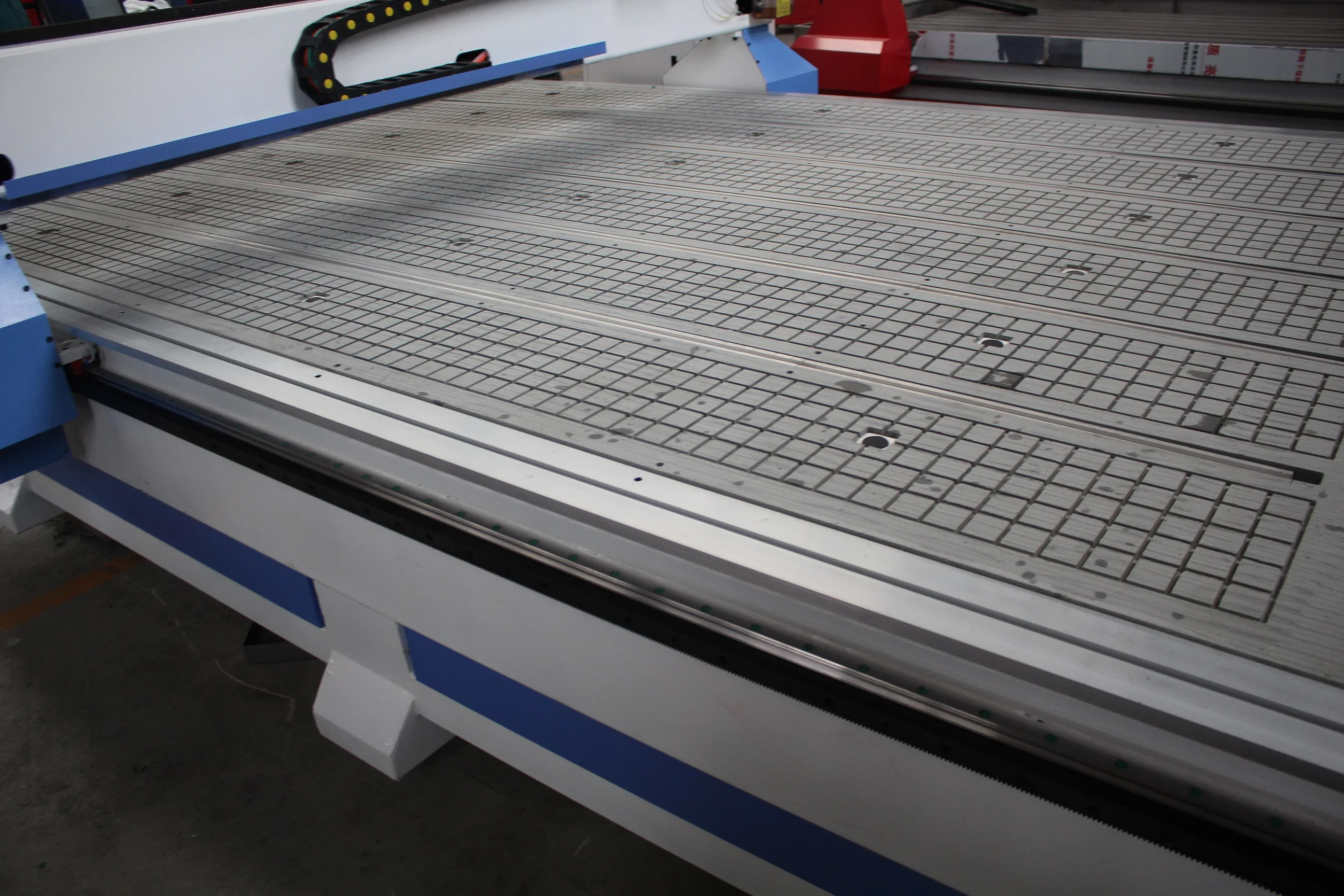

8.The vacuum table holds tightly the carving materials which makes operating more reliable and convenient.

performance parameter

|

number |

Description |

parameter |

|

1 |

XYZ working area |

2000*3000*200mm |

|

2 |

Table size |

2180*3500mm |

|

3 |

XYZ travel positioning accuracy |

±0.01mm |

|

4 |

XYZ repositioning positioning accury |

±0.01mm |

|

5 |

Table surface |

Bakelite vacuum table |

|

6 |

frame |

steel |

|

7 |

drive system X-Y axis |

Rack actuation |

|

8 |

drive system Z axis |

Ball screw |

|

9 |

Spindle power |

3/5.5kw spindle |

|

10 |

Max velocity |

50m/min |

|

11 |

Max working speed |

25m/min |

|

12 |

Spindle speed |

0-24000rmp |

|

13 |

work mode |

Stepper |

|

14 |

Working voltage |

AC220V/380V |

|

15 |

Command language |

G code |

|

16 |

Interface |

USB |

|

17 |

Operating system |

DSP/Mach3/Ncstudio |

|

18 |

Flash memory |

128 |

|

19 |

X-Y resolution |

< 0.025mm |

|

20 |

Software environment |

Ucancam type3 artcam |

|

21 |

Running environment |

Temperature:0-45°C |

|

22 |

Paking size |

3750*2150*2200mm |

|

23 |

Net weight |

1700kg |

|

24 |

Gross weight |

2000kg |

Customers

Our Services

Training and Use

1. We will supply with the machine operation manual in English version for installing and operation.

2.Customer can come to our factory training .

3.Our engineer can go to customer's factory training.

Warranty and After service

1. Our warranty is 2 years counting from the date when the Machine arrives at the port of

destination.

2. We will supply after service 24 hours,customer can contact us any time.

3.When some problems can’t be solved by customers, our engineer can go to door to help.

FAQ

Questions and answer:

Q1.how to get the most suitable machine and best price

please tell the material you want to working on ?

How to working on it ? Engraving ? Cutting ? Or other ?

What’s the MAX size of these material ?( length ? Width ? Thickness ?)

Q2.What is the payment?

The payment is 30% or 50% T/T or Alibaba trade assurance in advance, balance after machine finished.

Q3.What is the producing time after order?

The proucing time is about 10-20 days depend on different machines.

Q4.If we don't know how to use the machine,can you teach us?

Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And if

you are busy ,we will have the special engineer to your country,but you need to bear some fee,like

tickets and hotel and meal.

Q5.How about your after-sales service?

we offer you 24 hours service phone,skype or whatsapp, our engineer also can go to door install or training.

Q6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

complete machine will be tested to make sure they can work very well before being out of factory.

The testing video and pictures will be available before delivery.

How to contact us:

Whatsapp/Wechat/Moblile: 008613256769091

Email: Sales04@ht-cnc.net

Website: www.ht-cnc.net , www.htlasermachine.com

Training and Use

Смотрите так же другие товары: