Новое поступление

Professional 10pc/set Black Nylon And Steel Chisel Set Stone Carving Knife Artist Woodworker Hand Tools For Shoushan Stones | Инструменты

Чип для хранения памяти IPhone 6S 6SP 7 7Plus Nand flash 64 128 256 ГБ предварительно загруженные

Наборы прокладок для ATLAS COPCO COBRA TT выключатель блока цилиндра база Картера полные

1 шт. винт T8 Torx с гайкой складной карманный нож металлический титан

New Arriva 250mm 304 Stainless Steel Capillary Tube OD 8mm 6mm ID 10mm 4mm 3mm 2.5mm 1pc | Инструменты

4 шт. Сменные угольные щетки Электрический ударный драйвер молоток дрель

Цифровой регулятор температуры Dixell управление размораживанием и вентиляторами

Характеристики

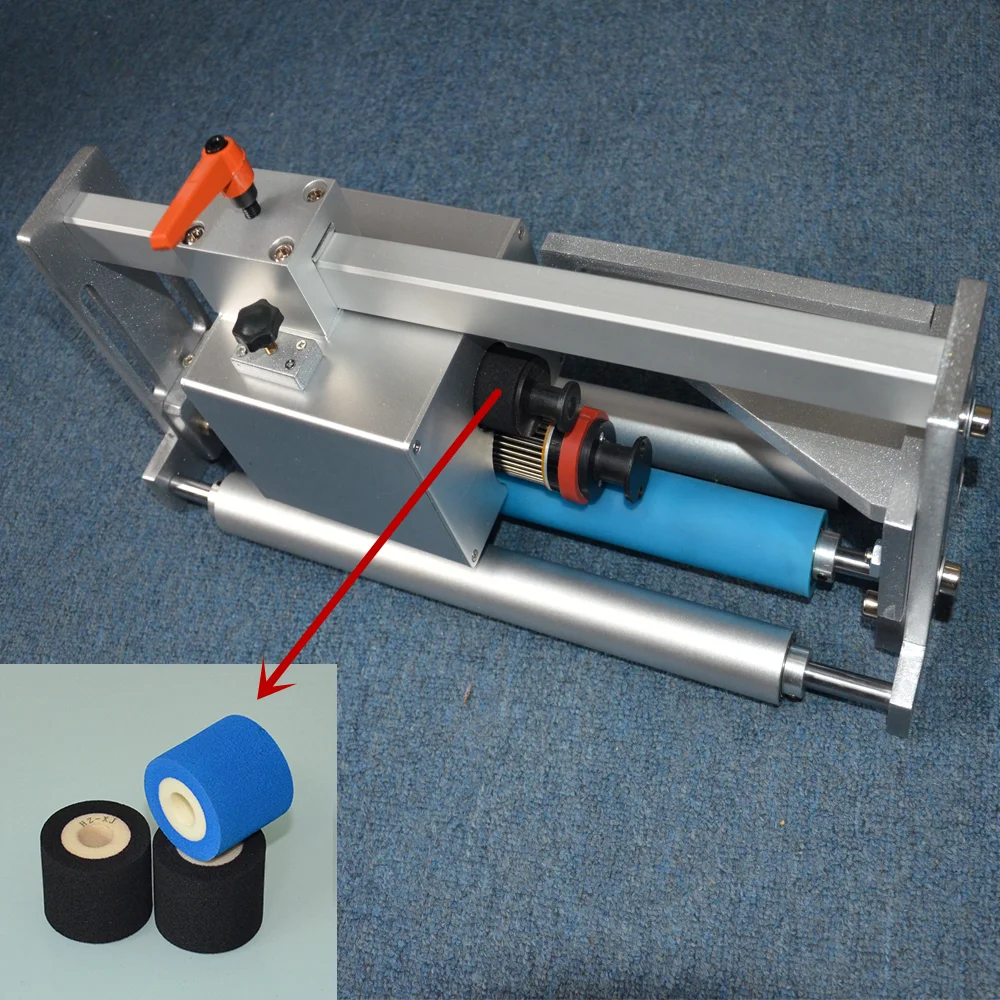

Black Diameter 36mm Height 40mm hot solid dry ink roller for continuous band sealer | Инструменты

История изменения цены

*Текущая стоимость 1 271,30 / lot уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-17-2025 | 1614.68 руб. | 1646.15 руб. | 1630 руб. |

| Jul-17-2025 | 1309.24 руб. | 1335.36 руб. | 1322 руб. |

| Jun-17-2025 | 1589.33 руб. | 1621.43 руб. | 1605 руб. |

| May-17-2025 | 1576.1 руб. | 1608.56 руб. | 1592 руб. |

| Apr-17-2025 | 1258.61 руб. | 1283.41 руб. | 1270.5 руб. |

| Mar-17-2025 | 1551.64 руб. | 1582.62 руб. | 1566.5 руб. |

| Feb-17-2025 | 1538.45 руб. | 1569.27 руб. | 1553.5 руб. |

| Jan-17-2025 | 1525.1 руб. | 1556.95 руб. | 1540.5 руб. |

Описание товара

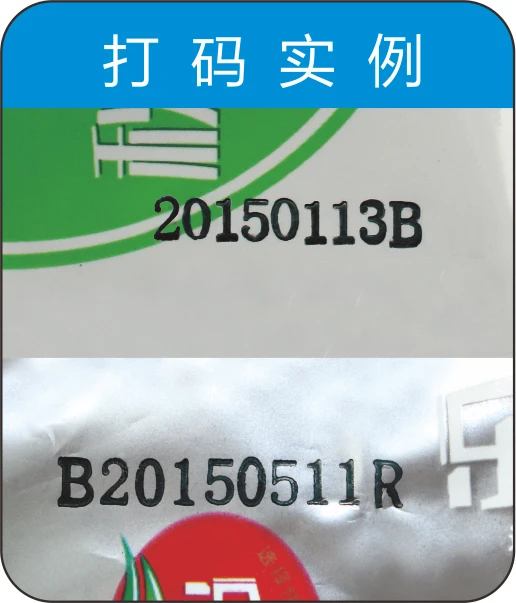

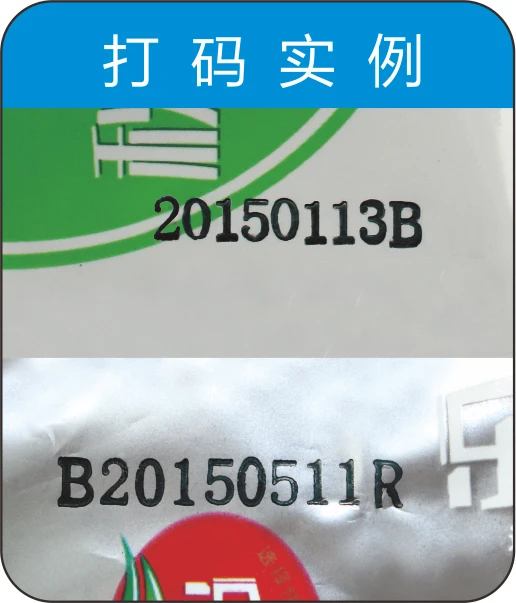

Black Diameter 36mm Height 40mm hot solid dry ink roller for continuouly

Product DescriptionWe are the manufacturer of Hot Ink roller, Hot Stamping foil,Coding foil and TTO ribbon(Thermal transfer over printer ribbon) for coding machine,since 2007 years.

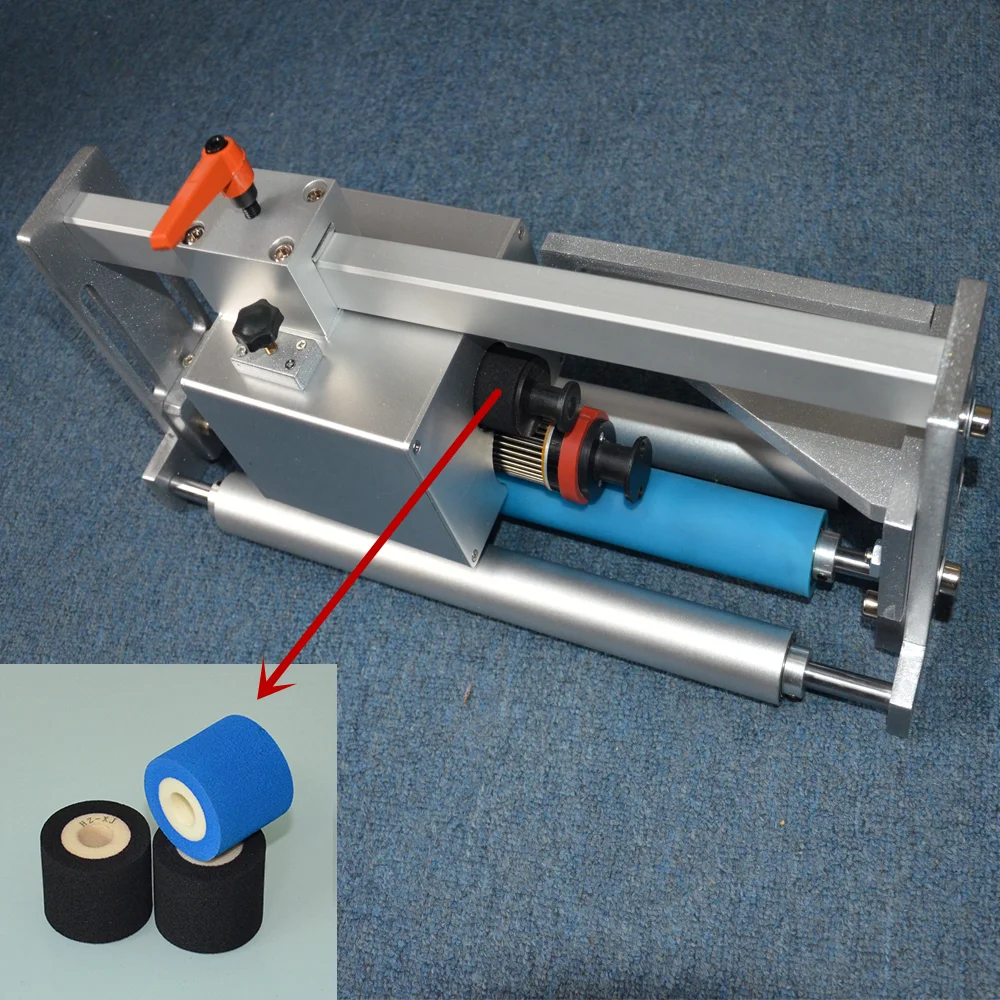

Hot Ink Roller is specialized foam roll loaded with a variety of hot melt inks, which is used to print production dates, expiry dates, batch numbers, and other related information on all kinds of package substrates for the food, cosmetic, pharmaceutical, automotive and the other industries. It is a specific consumable working with many different date coders & marking printers,such as HZ100,HZ300,MY380,MY300 and so on

.

Our HZ-XJ hot ink roller is to print expiration date, production date on Paper and Plastic Packaging bags

Hot Melt Ink Rolls are designed to be used in high many different high speed date coding and lot number marking printers which use stamps affixed to a rotating drum which contacts a heated urethane roll impregnated with an ink / paraffin formulation. Once the print head is covered with the hot ink, the rotating drum deposits the ink mixture on the label or packaging substrate. The ink rolls themselves are hard and dry to the touch at room temperature. However, when plugged into the printer, the roll itself is heated inside the printer, and the ink becomes liquid. Once deposited on the substrate, the ink dries almost instantly and creates a mark that is permanent and visually readable. The result is a visually readable date code, which is simple and extremely cost effective. These hot ink rollers have following quality:

Coding Products' hot ink rolls are designed especially for hot ink contact printers. We develop and manufacture specialized foam rolls that are friction loaded with a variety of hot melt inks. Rolls are available in five different inks, twelve different colors and in nine different roll sizes and can accommodate horizontal/vertical printing applications at any line speed. Our hot ink rolls are ideal for a wide assortment of flexible packaging contact coding ink applications

| Type | HZ-XJ Hot ink roller |

| Color | Black, Red, Blue, White |

| Size |

Dia36*12, Dia36*16, Dia36*32, Dia36*36, Dia40*40, Dia48*55 Dia35*10, Dia35*15, Dia35*30, Dia35*35, Dia40*40, Dia48*55 |

| Working Temp |

90---130 Degree |

Working on an ink roll coder printing on plastic film or paper, the ink roll is able to products at high speed many thousands of instant dry, highly legible print that has good adhesion and rubbresistant property. No mess and solvent free printing is another advantage of using ink roll for your coding requirement.

Main Features

1)Can achieve quickly printing words, Easy to use,Anti friction,Not easy to fall off, Quick-drying, No-Pollution

2) Widely used in MY380 ink roller coding machine, Marking machine, Sealing machine.

3) Widely used in Pharmaceutical, Food, Dairy products, Health products, and other Packaging industries.

4) To Print Production Date, Batch Number, and word label on the outer package

5) For Paper, PP, PET, PE, PVC on different plastic packaging bags

Hot Melt Ink Rolls are designed to be used in high many different high speed date coding & lot number marking printers which use stamps affixed to a rotating drum which contacts a heated urethane roll impregnated with an ink/paraffin formulation. Once the print head is covered with the hot ink, the rotating drum deposits the ink mixture on the label or packaging substrate.

The ink rolls themselves are hard & dry to the touch at room temperature. However, when plugged into the printer, the roll itself is heated inside the printer, & the ink becomes liquid. Once deposited on the substrate, the ink dries almost instantly & creates a mark that is permanent & visually readable. The result is a visually readable date code, which is simple & extremely cost effective. Hot ink roller in various sizes is also available as per customer’s requirements. Along with the PCS - hot ink rollers, BRASS TYPES are also available to be used with it.

Packaging & Shipping

Packaging & Shipping

We pay high attention to Product Quality, Technological Innovation, according to the ISO9001 Quality Management System.

And our product have kinds of certification such as SGS,ISO,MSDS,as you know,our clients are food and pharmacy factories or companies , so we must guarantee the product's quality.

| Size |

Pieces per carton |

Details per carton |

Weight KGS |

| Dia36*16 | 480 |

One Carton=20 boxes; Total is 480pcs |

8 |

| Dia36*32 | 240 |

One Carton=20 boxes; Total is 240 pcs |

8 |

| Dia36*36 | 216 |

One Carton=18 boxes; Total is 216 pcs |

8 |

| Dia36*40 | 216 |

One Carton=18 boxes; Total is 216 pcs |

8 |

| Dia40*40 | 216 |

One Carton=18 boxes; Total is 216 pcs |

9 |

| Note: we can produce any size and color | |||

We always insist on Excellent Quality, Sincere Services Corporate Philosophy, providing the flexible packaging coding solutions.

We have already established business with many clients in Philippines, Vietnam, Thailand, Malaysia, Singapore, Indonesia, Bangladesh, India, Pakistan, Iran, Saudi Arabia, Turkey, New Zealand, Russia, Egypt, Kenya, Canada, the United States, Mexico, Columbia, Bolivia, Argentina, Australia in the world

They are widely used in Food, Pharmaceutical, Cosmetics, Electronics, Logistics, Office and Advertising industries.

Henan Union Coding Tech Co., Ltd. is a manufacturer for coding and marking consumables, including: TTO ribbon(Thermal Transfer Over printer ribbon),Coding foil, Hot ink roller, Label paper,Coding machine and TTO Intelligent Printer.

Our goods are used in coding/marking inks, secondary packaging machines, batch-printing systems and coding machines for marking of statutory/variable information on packaged goods, such as Batch No., Date Of Mfg., Expiry Date, Lot No., Pkd No., M.R.P. etc

Our factory has 80 employees and 20 coating production lines, producing 380 million square meters packaging consumables every year. We have 20 National Invention Patents and always insist on:“Excellent Quality And Sincere Service”Corporate Philosophy, providing the flexible packaging coding solutions.

We have the Self-operate Import and Export License, and already established business with many regions, including Asia, Africa, North America, South America, Europe, etc.

Our coating and producing-line and a corner of the warehouse

FAQ

1, The Printing times:

The Printing times determines the quality of the ink roller.

The size 36*32, the printing times is about more than 100000 times

The size 36*16, the printing times is about more than 20000 times

2, Using temperature :

The solid ink need time to melt. If the temperature is lower, the solid ink can not melt, so the printing times will be reduce

3, The preheating 10 or 15 Minutes :

Hot ink roller is loaded into ink roller coding machine

Start the ink roller coding machine,

Heating temperature to 130 degrees,

Preheating about 10 minutes, until the ink roller surface softening, then you can use

4, More printing times :

With the increase of printing times, ink will gradually reduce, then increase the printing temperature, about 5 to 10 degrees, the printing times will be increased

Смотрите так же другие товары: