Новое поступление

Модуль питания MT3516 IGBT ИС выпрямительный мост RECT 35A 1600 в MT 3516 MT-3516 | Обустройство

DC Brushless Motor Regulator 5-12V 1.5A 15W 0%-100% PWM Speed Controller BLDC Driver Board Three Phase No Hall Governor | Обустройство

ADXRS620BBGZ BGA AD XRS620BA BGZ IC GYROSCOPE YAW RATE 32-CBGA ADXRS620BGZ | Обустройство дома

high power 24V 300A 360A 400A dc controller for forklift lift platform | Обустройство дома

Контроллер включения/выключения IC PB TSOT23 LTC2954CTS8-1 # PBF SOT23-8 TRPBF LTC2954CTS81 LTC2954CT 3 шт./лот

Бесплатная доставка контроллер двигателя беговая дорожка запасные части SHUA OMA

WS55-22 ER11 500 Вт бесщеточный электродвигатель вращения шпинделя комплект 12000р/мин

Характеристики

24v 150w 180w pm dc motor speed controller reversible pwm for wire feeder | Обустройство дома

История изменения цены

*Текущая стоимость 3 039,70 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Aug-18-2025 | 3860.26 руб. | 3937.65 руб. | 3898.5 руб. |

| Jul-18-2025 | 3130.45 руб. | 3193.23 руб. | 3161.5 руб. |

| Jun-18-2025 | 3799.60 руб. | 3875.72 руб. | 3837 руб. |

| May-18-2025 | 3768.73 руб. | 3843.47 руб. | 3805.5 руб. |

| Apr-18-2025 | 3009.40 руб. | 3069.62 руб. | 3039 руб. |

| Mar-18-2025 | 3708.35 руб. | 3782.46 руб. | 3745 руб. |

| Feb-18-2025 | 3677.10 руб. | 3751.45 руб. | 3714 руб. |

| Jan-18-2025 | 3647.41 руб. | 3720.43 руб. | 3683.5 руб. |

Описание товара

factory wholesales 24v 150w 180w pm dc motor speed controller reversible pwm dc controller for wire feeder

Model: DC24/20BL-4Q02

1. PULSE WIDTH MODULATION

Motor runs quieter, with greater efficiency and less maintenance, longer life.

2. SMT technology, small size

3. Low noise during operation, high efficiency, and low maintenance cost which better enhance the service life of DC motor.

4. ENABLE / BRAKE / DIRECTION TERMINALS

Choose a function by simply opening or closing a dry contact or through an open collector transistor.

5. STATUS LEDs

Power and Fault LEDs provide a visual status of the drive.

6. Forward and reverse can be set separately

It doesn’t need external reversing contactor and will not result in electric motor parts or other components overheating or burning down.

7. Output current can be set

8. Torque compensatio

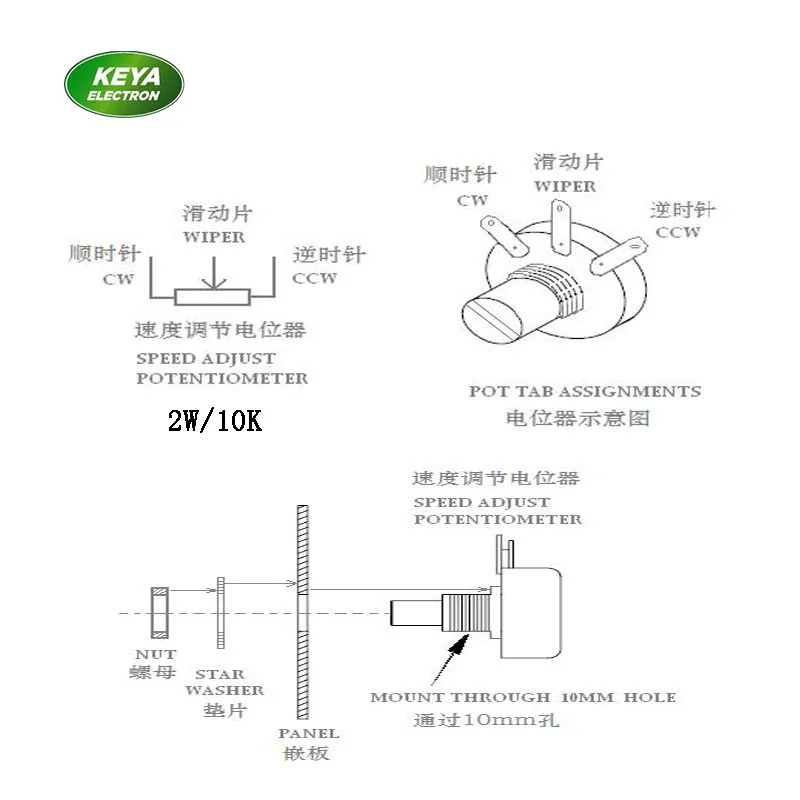

9. Standard analog control mode: Analog:0-5V or potentiometer

10. Over voltage & less voltage protection

11. OVER TEMPERATURE PROTECTION

Drive will fold the output power back to prevent from overheating. Drive will fault if it still remains too hot.

| Specification for DC24/20BL-4Q02 | |

| Input voltage range | DC24V (if you need 12V, 48vdc, kindly leave a message when place the order) |

| Max output current | 20A |

| Operating mode | Speed mode, Torque mode |

| Control ways |

PWM, Potentiometer, analog signal 0-10V (if you need 0-5v signal control, please leave a message when place the order) |

| Protection | Abnormalitise like over current, overheating, over voltage, less voltage and short circuit will start the protection function. |

| Temperature protection | When the temperature is 70, the controller will reduce output by overheating protection and stop output. |

| Working Temperature | -10 -- +50 |

| Ambient humidity | Relative humidity less than 80RH |

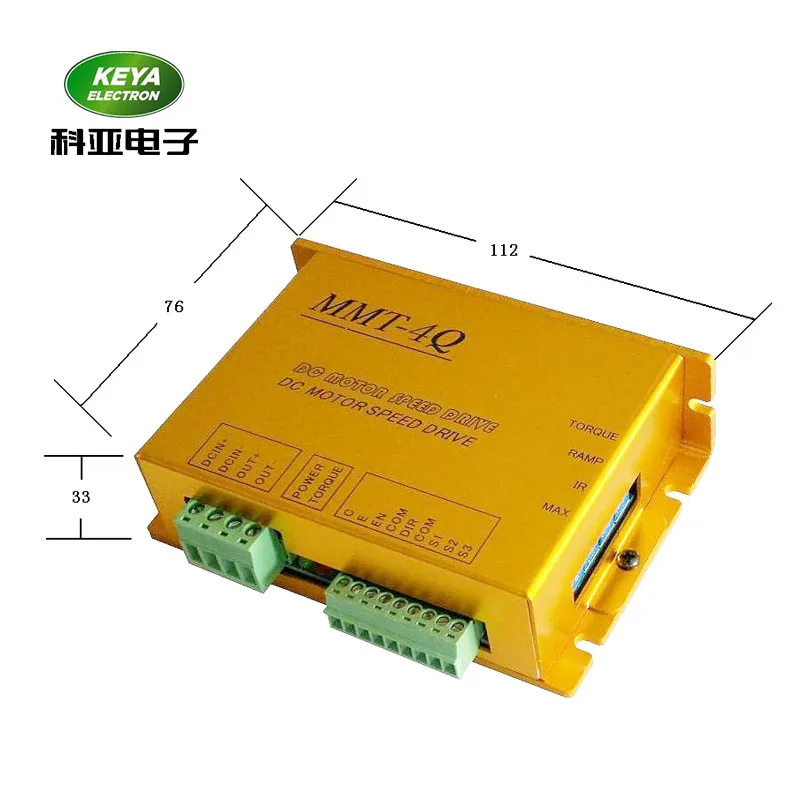

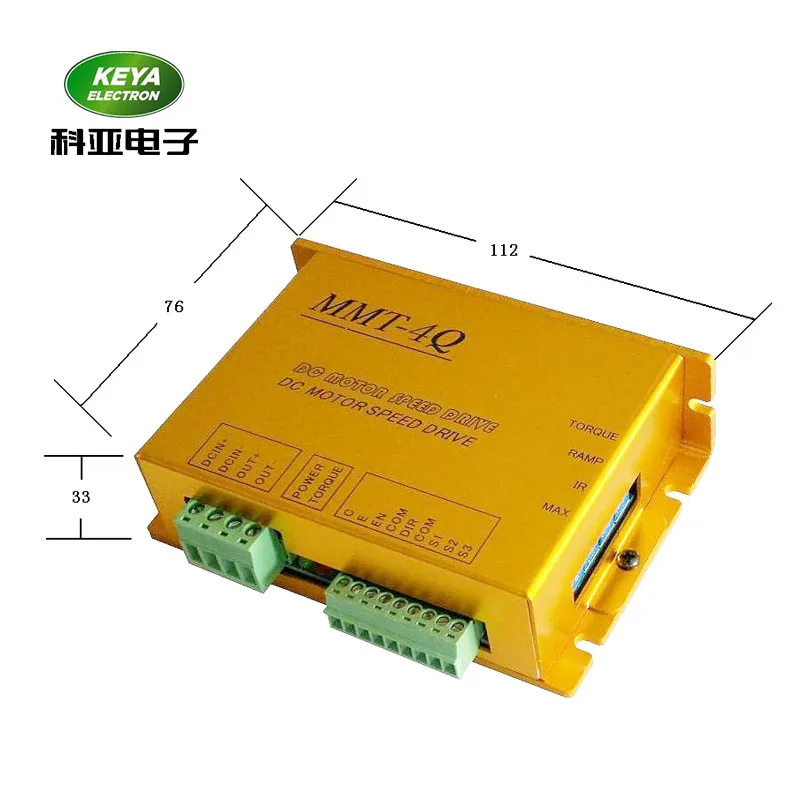

| Size | L*W*H = 112*76*33 mm |

| Weight | 250g |

factory wholesales 24v 150w 180w pm dc motor speed controller reversible pwm dc controller for wire feeder

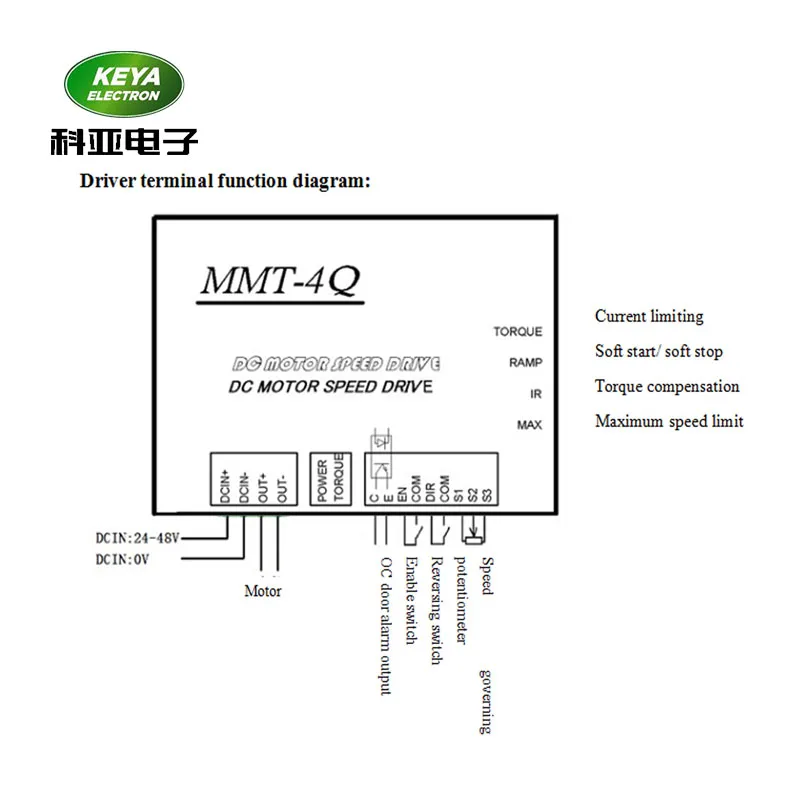

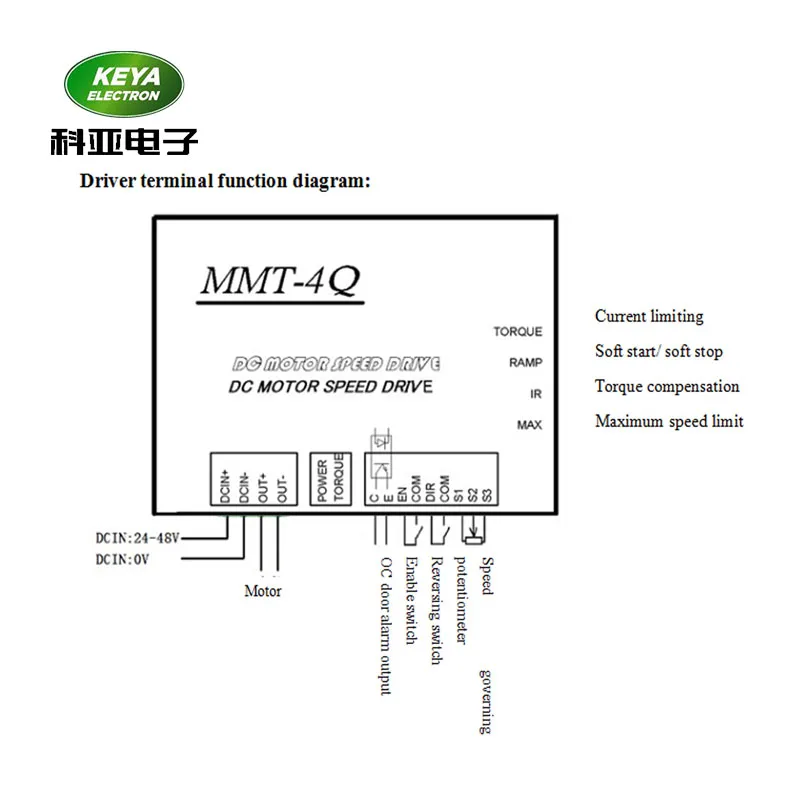

Description of control terminal’s functions:

1. EN (enable control)

During motor operation, simply connect/ disconnect EN with COM to control the start and stop of motor

Connect EN terminal with COM, EN terminal is effective, at this time regulate external speed potentiometer and motor is in normal operation.

EN terminal suspends in the air or is not connected, EN terminal is invalid; circuit of controller is blocked and motor stops.

2. DIR (direction control)

During motor operation, simply connect/ disconnect EN with COM to reverse the motor rotation. It doesn’t need external reversing contactor and will not result in electric motor parts or other components overheating or burning down.

Connect DIR terminal with COM, DIR terminal is effective, motor is in negative rotation.

DIR terminal suspends in the air or is not connected, DIR terminal is invalid; motor is in positive rotation (runs in opposite direction as above mentioned).

3. C E (OC door alarm output)

The internal design of “OC door alarm output” is that over-current signal is transmitted through an opto-coupler to give alarms. When over-current is detected on the controller, over-current signal will be immediately sent to diode of opto-coupler for break over and then transmitted to C, E ports. The client can wire as their own requirements, as shown in Figure 1, connect to over-current indicator,

Figure 2, relay actuation after over-current to give alarms.

Internal wiring diagram of “OC door alarm output” is shown as follows:

OC door alarm output

Alarm indicator output

Figure 1: Wiring description of alarm indicator output

Relay coil

Figure 2: Wiring description of alarm relay output

4. S1 S2 S3 signal output terminal

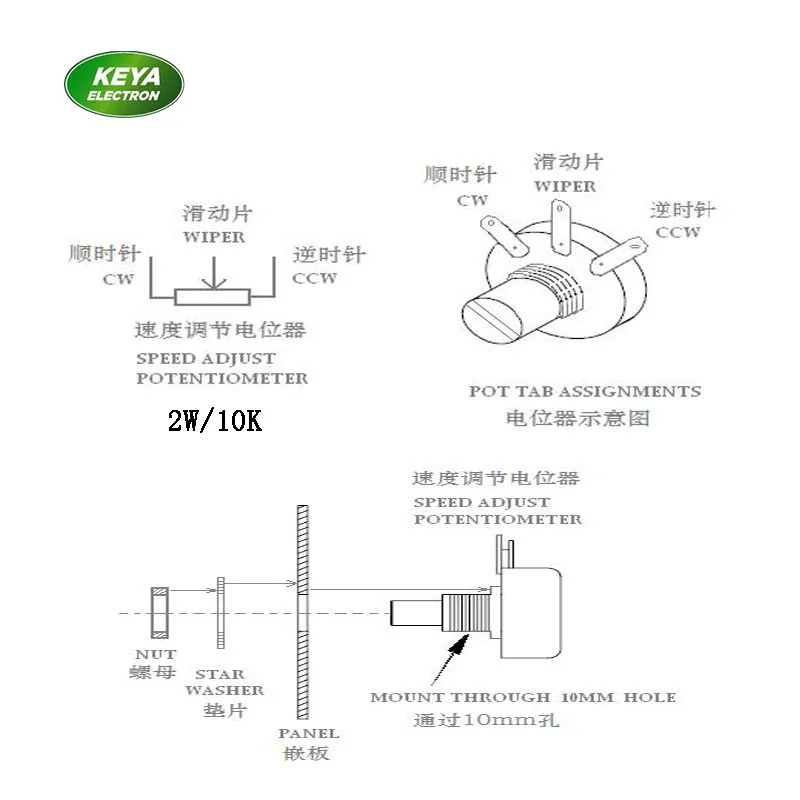

Such controller has two control modes of external speed potentiometer control and external analog quantity input. Description of various terminals is as follows:

S1 Terminal: external power+10V ,

S2 Terminal: signal input terminal

S3 Terminal: GND (grounded).

4.1 When external speed potentiometer control is used, S1, S2, S3 terminals shall be connected with external potentiometer as shown in VI. Driver terminal function diagram to regulate external potentiometer for speed governing

4.2 When external analog quantity input control is used, speed can be controlled through S2 and S3 input, both 0-5V and 0-10V are OK.

Description of indicator:

1. POWER (Green) power indicator

If the controller is charged, this indicator lights up to indicate that controller is under normal operation.

2. TORQUE (Red) over-current indicator turns red to indicate that output current of the controller exceeds client’s preset current, and the controller will automatically limit the output current to such value.

Regulation description of functional potentiometer:

MAX (maximum revolving speed limit)

It is used for limiting motor’s maximum revolving speed. Increase in clockwise rotation and decrease in counterclockwise rotation.

IR (Torque compensation)

Regulate “IR” enable motor work under different loads and keep revolving speed constant (normally factory default is 0), Increase in clockwise rotation and decrease in counterclockwise rotation.

RAMP (soft start/ stop)

Regulate “RAMP” to set motor’s starting and stopping time (1-20 S). Increase in clockwise rotation.

TORQUE (current limit regulation)

Regulate “TORQUE” to set over-current protection value of the controller; regulating range is 0-20A, Increase in clockwise rotation and decrease in counterclockwise rotation. When reaches over-current limit value, over-current indicator (Red) lights constantly and current is be limited to such value, at this time, continue to regulate the external potentiometer, current value is invariant( i.e. amplitude limiting).

24v 150w 180w pm dc motor speed controller reversible pwm dc controller for wire feeder

Jinan Keya Electron Science and Technology Co., Ltd, founded in 2001, has been trading in the research &development, manufacturing and sales of DC Servo motor and Servo control system for 15 years. Company set technology, talent, management and other resources advantages, to effectively integrate, has maintained a healthy, stable and rapid growth.

The company has adopted ISO9001:2015 quality management system certification, products through the CE certification. More than 3000 large and medium-sized domestic equipment manufacturers designated as supporting products, and exported to the United States, Europe, Southeast Asia and other countries.

Product range: brushless dc motor, dc servo motor, bldc controller, bldc driver, brushed dc motor speed control

We devote ourself to Research & Development, welcome Costom-made products, if you need some unusual products, let's have further communication.

24v 150w 180w pm dc motor speed controller reversible pwm dc controller for wire feeder

Delivery time: 1-3 working days after receive the payment

| Products Application Cases Display |

| FAQ |

1. Q: What are your main products?

A: We produce various kinds of dc motor & controller.

2. Q: How long have you been in this field?

A: More than 15 years in this field.

3. Q: Do you have your own R&D team?

A: Yes. R&D is our core competitiveness, continuous innovation is just what we are seeking for all the time. Some of our engineers have more than 20years experience in the industry, and we also cooperate with colleges, scientific research institutions and large enterprises.

4. Q: How soon can you deliver the goods?

A: That depends on the exact model you order. For regular products, usually we will prepare some units in stock, we can deliver them within 3 working days.

5. Q: Can you make the product according to customer’s requirements?

A: Yes, welcome costom-made products.

6. Q: What is your payment term?

A: You can pay by TT, Paypal, Western Union.

| Contact |

Thank you for your visiting, when you need further more information, kindly contact Nancy directly, the detail information will be provided for you within 1 hours.

Смотрите так же другие товары: