| 1) The machine’s body is strong, high-precision, reliable and durable. 2) Imported high-precision ball screw, which moving smoothly, to ensure high precision. 3) Well-known water cooling spindle, strong cutting ability, low noise, to ensure the machine working for long time. 4) High-performance drive stepper motor to ensure the machine’s high speed and accuracy. 5) Perfect design, top quality accessories, to minimize the machine’s failure rate. 6) Break point specific memory to keep the carving status when power off, processing time forecast and other functions in case of the accidental power outages. 7) compatible Type3/ Artcam and so on a variety of CAD/CAM design software. 8) Mach3 is easy to operate and when you meet some questions, we could make teamviewer for you.Also NK105 DSP, Nc-studio for option.

Cnc router 1200*1200 details parameter | | Description | Parameter | | 1 | X-Y-Z Working Area | 1220x1220x120mm | | 2 | Table Size | 1340X1545mm | | 3 | X-Y-Z Traveling Positioning Accuracy | ±0.03/300mm | | 4 | X-Y-Z repositioning Positioning Accuracy | ±0.04mm | | 5 | Lathe Structure | Cast Steel | | 6 | X, Y Structure | Ball Screw, Shaft Linear Bearings | | 7 | Z Structure | Ball Screw, Shaft Linear Bearings | | 8 | Max. Consume Power | 3.5Kw | | 9 | Max. Speed | 0-6000mm/min | | 10 | Max. Working Speed | 0-3000mm/min | | 11 | Spindle Power Motor | 1.5kw water-coolant spindle (Option: 1.5kw HSD) | | 12 | Spindle Speed | 0-24000RPM | | 13 | Drive Mode | Stepper Motor | | 14 | Working Voltage | AC220V/50/60Hz | | 15 | Command | G Code, *uoo, *mmg, *plt | | 16 | Operating System | DSP System | | 17 | Interface | USB | | 18 | Flash Memory | 128M | | 19 | Collet | ER18 | | 20 | X-Y-Z Working Delicacy | <0.01mm | | 21 | Software | Type3, Ucancam, Artcam | | 22 | Running circumstance | Temperature: 0°C~45°C Relative humidity: 30%~75% | | 23 | Packing Size | 1800x1830x1450mm | | 24 | Net Weight | 400KG | | 25 | Gross Weight | 450KG | | All parameters above subject to change without prior notice |

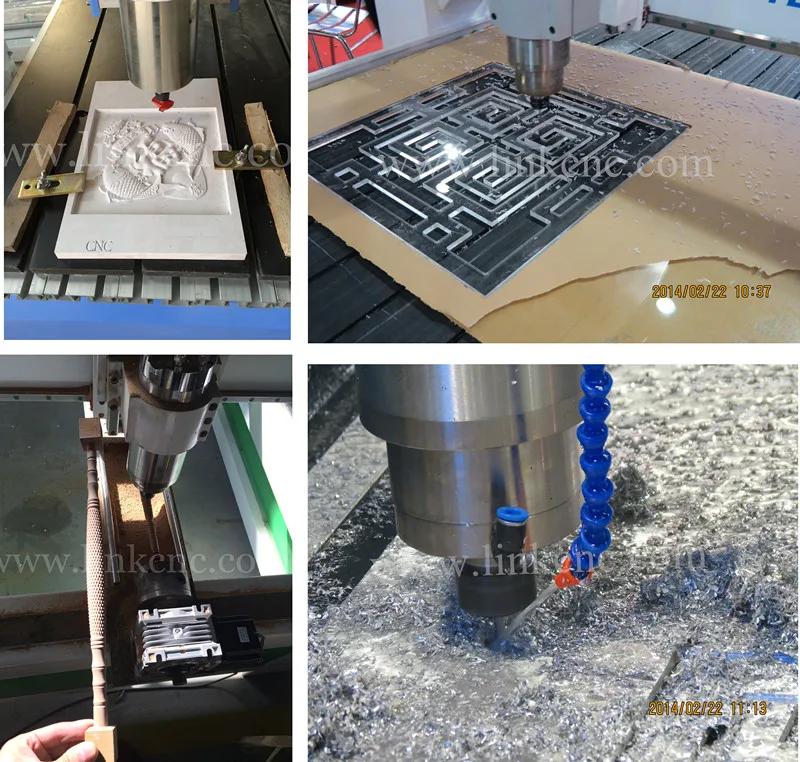

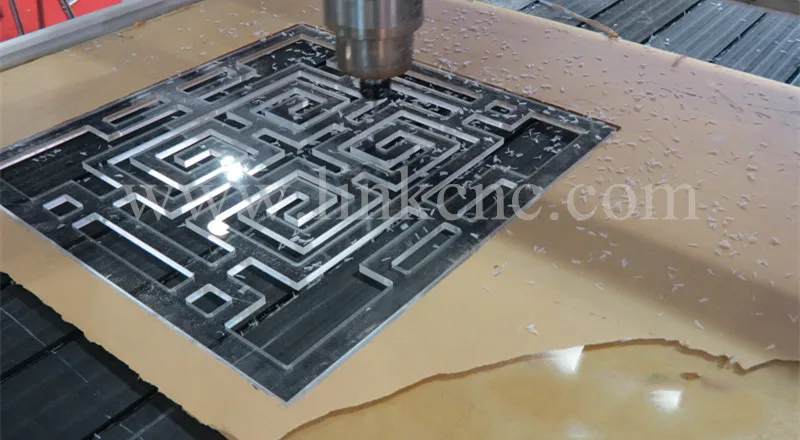

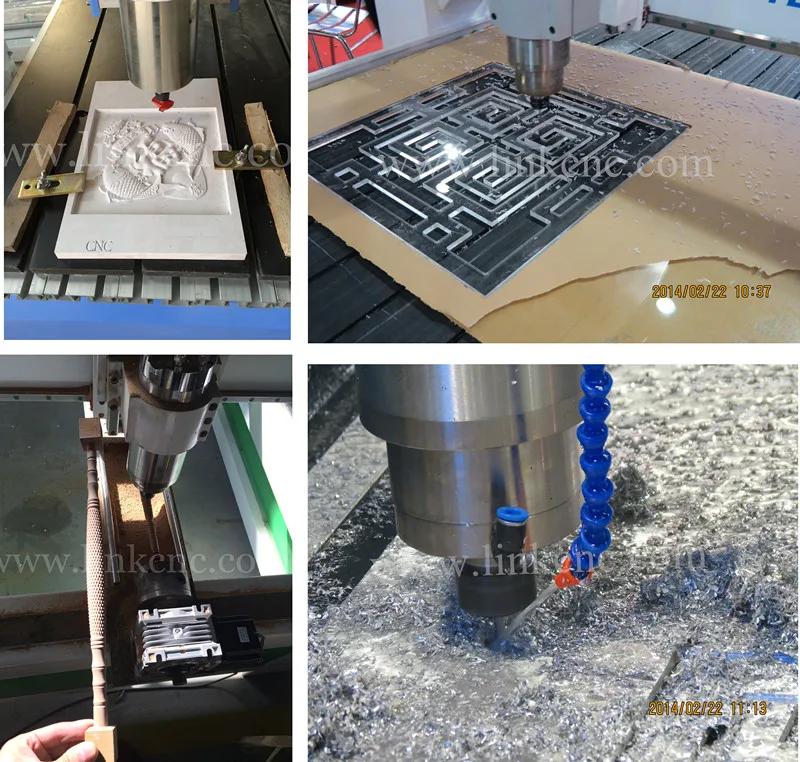

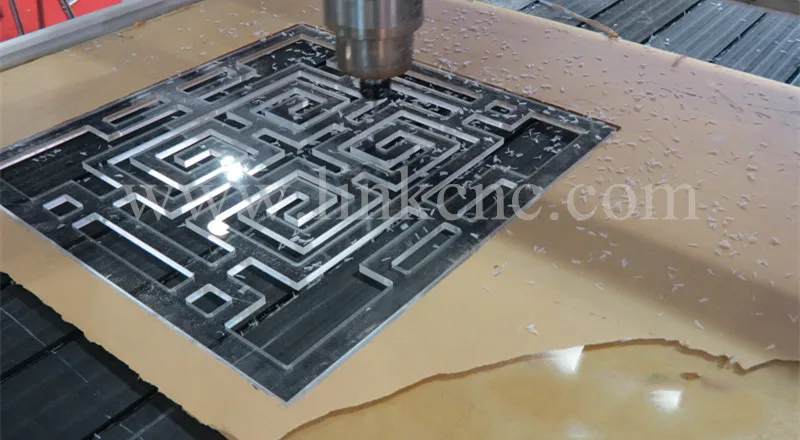

| Features of cnc router machine: 1. Efficient:It need just a few minuts or several quarters to make a comman PCB. 2. Automatic:Abolish traditional “film, sensitization,fixation,corrosion,wash,drilling”working progress,to make a board only need finish PCB file design of ROTEL,the reft can be finished automatic. 3. Accuracy:The error is less than 1mil for drilling,more pins components can be located easy, avoid plug-ins for manual drilling difficulties. 4. Cheap:The price of ACUT PCB cnc router only a fraction of imported machine,since the raw materials are much cheaper, reduce the research and development spending. 5. Artistic:Beautiful, luxury and elegant in design. 6. Environment: Abolite of the traditional method caused by chemical pollution to the environment. Pictures of cnc router machine: ![img_0680_]() ![img_0701_]() ![img_4796_]() ![img_4808_]() ![img_4818_]() ![1212-11]() | Functional index | 6090 | 1212 | 1218 | 1325 | | Working area | 1094*800mm | 1550*1320mm | 2220*1440mm | 2900*1440mm | | Travel of engraving | 900*650*70mm | 1200*120*100mm | 1200*1800*100mm | 1300*2500*100 | | Max. speed | 6000mm/min | 6000mm/min | 10000mm/min | 12000mm/min | | Engraving spingle | inverter 800W | inverter 1500W | inverter 1500W | inverter 2200W | | Power | 1.5KW | 1.5/2.2KW | 1.5/2.2KW | 3/5.5KW | | Rotational speed of spindle | 6000~24000rpm | | Manner of receiving data | USB interface / PCI card | | Capacity of memory | 32M | | Format of instructions | Gcode / HPGL | | Cutter | Φ3.175orΦ6.00(max Φ13.75) | | Power supply | AC220/50Hz | | Packing size | 1.15*1.45*1.5m | 1.75*1.75*1.55m | 2.3*1.75.1.55m | 3.2*2.2*1.8m | | Electric powernbsp | 400W | 400W | 600W | 600W | | Driving system | Stepper | Stepper | Stepper | Stepper | | Weight | 300kg | 450kg | 600kg | 900kg |

| |

|